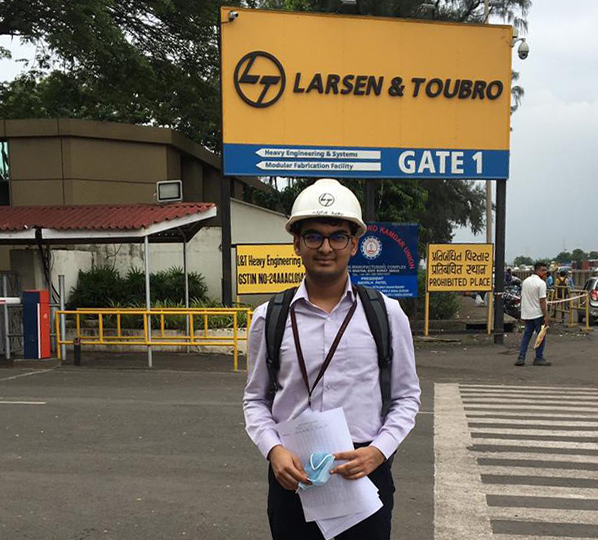

Larsen & Toubro Ltd.

Summer project intern at the Large equipment manufacturing facility, HZMC.

About: L&T Heavy Engineeing Division, Hazira

L&T’s Hazira campus is a multi-facility campus that covers a Modular Fabrication Facility (MFF), as well as Heavy Engineering, Defence & Shipbuilding, and Power equipment manufacturing facilities. This modern, coastal complex is situated on a vast plot near Surat in Gujarat. The factory buildings cover over 34,500 sq. m. and the complex has a load-out quay on the banks of the river Tapi close to the Arabian Sea.

Hazira campus is equipped to manufacture extra-large and very heavy equipment for power projects, chemical, refinery, petrochemical & fertilizer industries, which can be shipped out via waterways. In addition, L&T’s Hazira complex has one of the world’s largest Forging facilities, large scale Material handling capabilities, a roll-on-roll-off slipway, and a Shipbuilding facility for high-tech vessels.

This newly established & ultra-modern Armoured Systems Complex (ASC) comprises of workshops with in-house advanced Robotic Welding Systems, CNC Machining, System Assembly & Integration facilities, Latest digital solutions for project monitoring, Integrated store management systems, Advanced metrology and a Special Purpose Mobility Test Track facility to roll out fully integrated Armoured systems from ‘plate-to-platform’ basis under a single roof of the complex.

L&T Defence Unit at Hazira also manufactures Underwater Platforms, Bridging Systems, Missile Launching Systems and various other equipment for Land & Naval forces.

Internship Project: IoT enabled welding stations

Apart from my day to day activities, I was responsible for curating a study project report on IoT enabled welding stations. Since, L&T, Heavy Engineering has also IoTised all their head welding stations with a single worker in a booth controlling multiple welding stations. These initiatives in welding and overlay operations have not only delivered huge productivity improvements but have also enhanced the safety of workers.

I interned as a summer project intern at Larsen & Toubro Ltd., Heavy Engineering Division, Hazira, one of the best manufacturing facilities in the world. While working as an intern, I was responsible for the design and analysis of various machine parts. The main project in which I was involved was in the design and development of an automatic cutting mechanism for the feeded strip in electro slag strip cladding (ESSC) welding process.